-MATERIAL ISSUE 5- CONTRIBUTE TOWARD A SOCIETY THAT COEXISTS WITH NATURE

KOKUYO Materiality Contribute toward a society that coexists with nature

Basic policy

Conservation of forests is a major imperative for us since we use plenty of timber (not least in our mainstay products of notebooks and office furniture). Over the years, we have worked to conserve biodiversity and reduce our use of hazardous materials in order to minimize our impact on the environment.We will ascertain the environmental impact of our business activities and work on strategies to mitigate these impacts to contribute toward a healthy planet, in which natural capital is balanced with business activities.

Metrics and targets for material issue

| Outcome | 2030 challenge goals | |

|---|---|---|

| KPI | ||

| We safeguard the planet by balancing business activities with natural capital. | We now disclose our carbon footprint and actions to minimize it, encouraging an eco-friendly attitude in the market. | Carbon footprint of business activities visualized and carbon neutrality achieved |

| Forest conservation: Forests thinned at 150 hectares a year | ||

| Reedbed conservation: Reeds trimmed at 1.5 hectares a year | ||

Accomplishments in 2023, plans for 2024

| Accomplishments in 2023 | Plans for 2024 |

|---|---|

|

|

Measuring environmental impacts

We are developing metrics to measure how well we discharge our responsibility as a company whose businesses use forest resources. The metrics, all describing an aspect of co-existence with nature, include understanding biodiversity, relationship between business and biodiversity, evaluation of raw material risks, and identification of risks to business sites and the surrounding area. With companies increasingly expected to disclose information in line with the Taskforce on Nature-related Financial Disclosures (TNFD), we are also monitoring this trend and working to understand what the requirements are.

Implementing the basic policy

KOKUYO Group’s policy on timber procurement

In 2011, we released a groupwide policy on timber procurement to enshrine our commitment to sustainable use of forest resources. Since our foundation, timber has served as an important resource in our products, such as paper. Recognizing the vital role forests play in mitigating global warming and supporting biodiversity, we aim to promote harmony with forests by ensuring that our timber procurement is legal, transparent, and sustainable.

KOKUYO Group’s policy on timber procurement

In procuring forest resources, we pledge to observe the following principles and continually strive for more ethical and sustainable procurement.

- Make procurement more transparent, mindful of the problem of illegal logging and related timber trade

- Choose timber suppliers in a more meticulous and scrupulous way to promote the sustainable use of forest resources

- Recognize the valuable roles that forests play in local communities and ensure that procurement activities preserve and facilitate these roles

KOKUYO Group Standards for Procuring Paper and Timber

In April 2024, we established the KOKUYO Group Standards for Procuring Paper and Timber. We satisfy these standards in our procurement of paper and timber. We will go further in ensuring that our procurement activities are sustainable—and that respect for people’s safety and human rights is upheld across our supply chain.

KOKUYO Group Standards for Procuring Paper and Timber

KOKUYO’s businesses are heavily dependent upon goods made from natural resources, in particular paper and timber. Paper and timber are renewable resources. KOKUYO’s businesses are therefore sustainable if they use paper and timber that has been managed responsibly. They will be unsustainable, however, if the natural resources that supply the paper and timber are managed irresponsibly. With this firmly in mind, we commit to sustainable procurement, whereby we safeguard or reinforce ecosystems and biodiversity underlying our businesses and respect the safety and human rights of all people across our supply chain.

- As a rule, we prioritize the use of paper and timber that is certified in an internationally reputed certification system.*

- If we are unable to use such paper and timber, we will use paper and timber that is confirmed to have satisfied the following legal criteria:

- The product can be traced back to the furthest upstream production site.

- Documentation is available certifying that the product complies with legal requirements in the territory of production.

- The product is not made from a species threatened with extinction.

- The product does not harm the ecosystem.

- The product does not harm the local environment or local community.

- We will only use recycled paper or timber that has been recycled legally following market circulation.

- We will routinely monitor the percentage of raw materials that satisfy the above criteria. Our goal for 2030 is to get this percentage to 100%.

- If the paper or timber in question has been certified but there is doubt about its sustainability, we may suspend the procurement of the product until we have confirmed that it meets these standards.

These standards apply to paper and timber, but we will follow these standards in our procurement of other raw materials too. We intend to set out separate sets of standards for other raw material categories.

Currently, these certification systems may include the Forest Stewardship Council (FSC®) and the Program for the Endorsement of Forest Certification (PEFC).

Certified as a procurer of legal and sustainable timber

We have been certified as a “procurer of legal and sustainable timber” by the Japan Office Institutional Furniture Association (JOIFA). In line with the requirements set out in the Act on Promoting Green Procurement, we strive to ensure that the timber we use is legal and sustainable by providing a paper trail to show how the timber is procured and used and by appointing the right people to manage this process.

Results of due-diligence review of timber compliance (in accordance with Timber Legality Certification Due Diligence System Manual —Furniture Edition)

In 2023, our due-diligence review of timber compliance revealed no potential legal issues with the timber we used. We will continue performing rigorous due diligence while finding ways to further enhance the manual’s effectiveness. You can view the manual (ver 1.4) by following the link below.

Timber Legality Certification Due Diligence System Manual (Furniture edition: Ver 1.4)How we have used forest resources

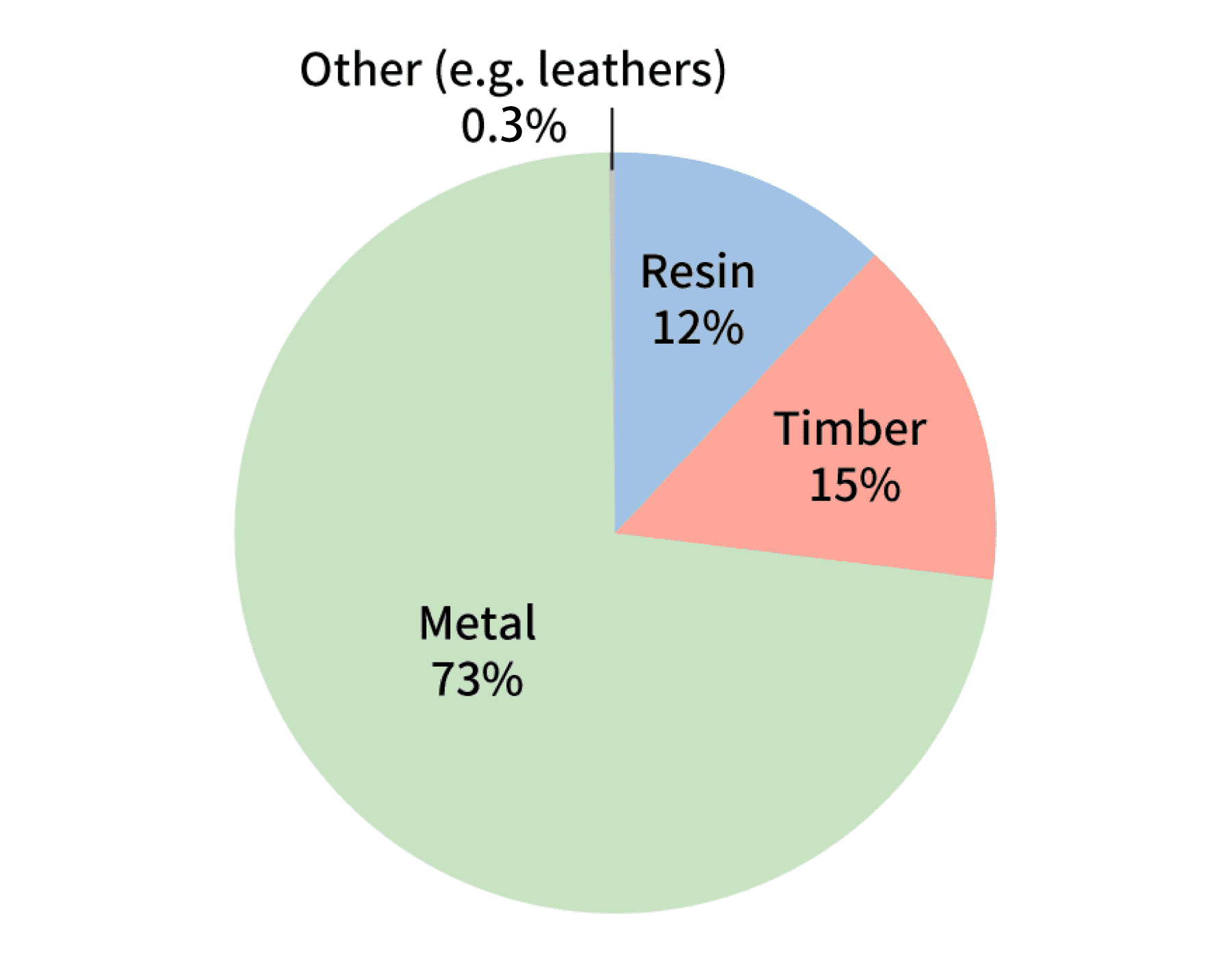

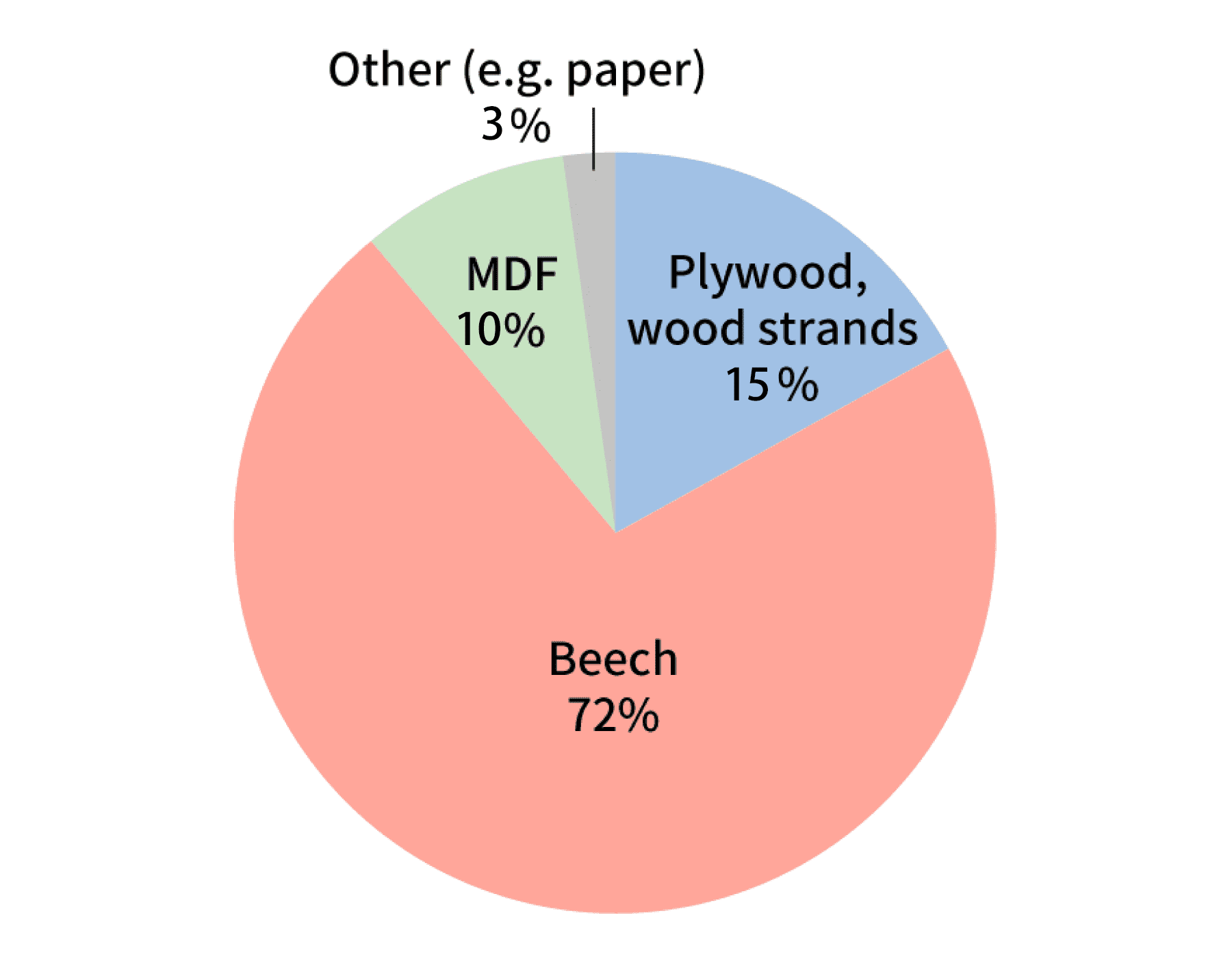

In 2023, we used around 6,958 tons of wood in furniture products. Of this wood, 17% consisted of rough-cut lumber that was made into solid wood or engineered wood (including plywood). The remaining 83% consisted of forest residues (byproduct from thinning or clearing) or engineered wood (including medium-density fiberboard and particle board) made from such. Each year, we report such data to JOIFA, the body that certifies us as a “procurer of legal and sustainable timber,” in compliance with the Act on Promoting Green Procurement. As per JOIFA’s reporting guidelines, we try to identify the wood species among the timber we use.

-

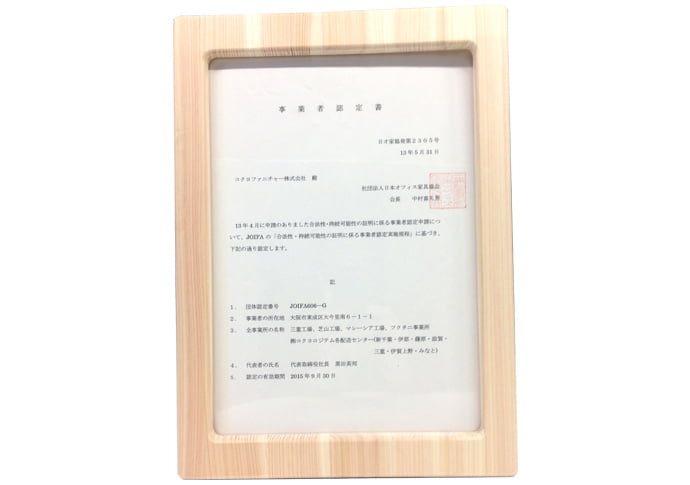

Materials used in furniture products

(excluding packaging) in 2023 -

Engineered wood versus rough-cut lumber

-

Tree species among rough-cut lumber used

Timber use survey

We conduct an annual survey to monitor the following data items for the timber used in our furniture products, including wood species, volume used, and country or region of origin. It is often unfeasible to identify the country or region of origin of the timber used in products, but we do our best to source the products sustainably.

| Tree species | Condition | Volume used (m3) | Country or region of origin |

|---|---|---|---|

| Ash | 4 | USA | |

| Kapur | Wood strands, veneers | 18 | Indonesia,Malaysia |

| Japanese cedar | Plywood | 4 | Japan |

| Beech | Engineered wood | 56 | Croatia,Germany |

| Poplar | 142 | China,Canada,USA | |

| Maple | 1 | USA | |

| Lauan | 365 | USA,Canada | |

| Rubberwood | Engineered wood | 16 | Thailand,Vietnam |

| Radiata Pine | Engineered wood | 2 | |

| Falcata | Engineered wood | 224 | Indonesia |

| Beech | Plywood | 15 | Germany |

| Meranti | 9 | Malaysia | |

| Total | 857 | ||

The data in the above table has been aggregated from the figures provided by each supplier. The data covers only wood from rough-cut lumber.

The table shows only wood species for which we could identify the country or region.

Using Japanese or local timber

As much as 67% of Japan’s landmass is covered by forests. Forests help prevent sediment runoff, contribute to water retention, and absorb CO2. They also provide a renewable resource. However, in much of the country’s man-made forests, which account for 40% of all the forests, these roles are not fully performed due to insufficient forest thinning.

In 1998, we started developing forest thinning equipment, releasing it to the market in 2000. By making our office products from Japanese timber that was harvested during thinning operations, we create new demand for wood while also contributing to sustainable forestry.

yuimori

Back in October 2006, we launched the Yui-no-Mori Project in partnership with the Taisho-cho Forestry Association (now the Shimanto-cho Forestry Association) in Kochi Prefecture. More recently, we launched Yuimori, a brand of wooden furniture made from timber harvested in Yui-no-Mori Project. By using Japanese timber, the brand contributes to harmony with nature. Yuimori products feature elegant and impactful designs along with the high quality required for office furniture. They are also designed for sustainable disposal.

The products were designed by Keiji Ashizawa, who boasts an extensive design portfolio from architecture to furniture. Furniture experts Tendo Mokko (headquartered in Tendo, Yamagata; represented by Yukio Kato) fabricated the designs, bringing out the timber feel. We contributed our own know-how in office furniture, such as ideas for making a chair comfortable.

Through Yuimori, we contribute to greater harmony with nature.

View the Yuimori webpage: yuimori

EF Counter, featuring modesty panels made from locally sourced timber

EF Counter is a series of modular counters that can be rearranged to suit changes in the organization or changes in desired use. With their universal design, the counters are friendly to the elderly and to wheelchair users. While part of the structure is made from standardized materials, the modesty panel is made from timber sourced from the locality in question. This arrangement ensures that the counters are no less functional and versatile than standard counters are. The table edge has a groove for securing a walking stick or similar items and a grip for wheelchair users.

The customizable counter protects user’s privacy and enhances the experience of using the amenity.

A walking stick rests securely on the edge.

The edge is easy for wheelchair users to grip.

FSC Certification

In 2003, we received chain-of-custody (COC) certification from the Forest Stewardship Council® (FSC). The FSC is an international non-governmental organization that runs a system of third-party forestry certification. Its purpose is to preserve forest environments by promoting a responsible form of forest management that benefits local communities and is economically sustainable. COC certification applies to the processing and distribution of FSC-certified products. The organizations in our group that have obtained COC certification are KOKUYO, Kaunet, and KOKUYO Product Shiga. The FSC has approved our products, including our printer paper and notebooks. In 2016, we received COC certification under the Programme for the Endorsement of Forest Certification (PEFC). The PEFC is a forest certification scheme. Its criteria is based on accepted intergovernmental standards. We aim to get more of our products certified for their sustainable use of forest resources. (FSC® C004748)

-

Printer paper (PPC Color Paper)

-

Reed paper

-

UU Chair

Yui-no-Mori Project

In 2006, we launched a project to conserve a private forest in the Taisho district of Shimanto, Kochi Prefecture, which we named Yui-no-Mori (“linkage forest”). In this project, we thin the forest and make effective use of the resulting timber. Our purpose is to lead the way in reviving manmade forests and restoring the link between the natural environment and local livelihoods. In 2007, the project was certified by the Forest Stewardship Council® (FSC®).Today, Yui-no-Mori has a surface area of 5,425 hectares, and a cumulative area of 2,053 hectares has been thinned. Kochi Prefecture has awarded us the “CO2 absorption certificate” since 2007. In FY2022, the forest absorbed 4,133 tons of CO2. The cumulative total (April 2006 to March 2023) stands at 76,222 t-CO2. In 2023, Yuimori (the brand of products made from timber harvested in the Yui-no-Mori Project) was honored at the 6th Eco Pro Awards and at the 2023 Japan Wood Design Award. The Yui-no-Mori Project itself has earned accolades too. In January 2022, it earned the grand prize in the “conservation in practice” category at the Japan Nature Conservation Awards 2022 Nature Conservation Society of Japan. In May 2022, it earned the “excellence award” (Forestry Agency Director-General Award) at Forests × Decarbonization Challenge 2022. In 2020, it earned a “sustainability action” commendation from the Ecological Life and Culture Organization and the “18th Corporate Philanthropy Award” from the Japan Philanthropic Association. In 2019, it won a commendation at the Low Carbon Challenge Cup 2019 and a “minister’s prize” in the corporate category of the Ministry of the Environment’s Good Life Awards. In 2018, it won a “Green Wave Award” prize at the Biodiversity Action Awards. In 2017, it won the Japan Wood Design Award.

*Related information:Yui no Mori

Kochi Prefecture confers certificate of carbon sequestration

On November 11, 2023, Kochi Prefecture awarded KOKUYO and Kaunet a CO2 absorption certificate in recognition of the fact that we had offset a total of 4,133 tons of CO2 (KOKUYO offset 3,497 tons and Kaunet offset 636 tons). The award ceremony was held at the Shimanto-cho town hall. Presenting the award, [First-name] Sakata (an assistant section chief) thanked the two companies for contributing over the years to Kochi’s efforts to preserve its environment, manage its forests, promote local industry, and support its PR. To help spread the word about Yui-no-Mori, Kaunet launched a scheme in 2008 whereby customers can use their loyalty points to fund the thinning work. In 2023, there were around 186 applications for the scheme.

The 4,133-ton offset represented 11% of the group’s total CO2 emissions in 2023 (36,829 tons).

FSC certification

Yui-no-Mori has enjoyed FSC certification since 2007.

Following a regular audit performed on August 24 and 25, 2023, the project was recertified by the FSC.

-

Presentation of CO2 absorption certificates

-

CO2 absorption certificate

-

An FSC certification audit in progress

Monitoring thinning outcomes

An important part of forest conservation is seeing the outcomes of thinning. We monitor these outcomes over the long term in partnership with Shimanto Forestry Association, Shimanto High School, and officials of Kochi Prefecture and Shimanto. On October 5, 2023, we measured the water quality of Shimanto River. On November 19, we conducted a vegetation survey.

*Related information:View the latest vegetation survey report from the students of Shimanto High School

Wildlife survey

We investigated the kinds of fauna that inhabit Yui-no-Mori.

On May 11, 2023, we teamed up with experts and students at Shimanto High School to install 12 cameras in locations in Yui-no-Mori. The cameras were installed in six locations, two in each (the locations were in Utsuigawa, Yoshikawa, and Shimotsui). The cameras recorded footage for six months, ending on November 7.

On June 16 and 17, an ornithologist helped us identify the birds that appeared in the footage.

Analysis of the footage revealed the presence of 11 types of mammals. One mammal species was the Japanese dormouse, designated as a natural treasure. We also identified 46 types of birds. These results confirmed that Yui-no-Mori remains biodiverse.

Students from Shimanto High School installing a camera

A camera in place

A Japanese dormouse (national treasure)

Mammals identified

| Order | Family | Common name | Binominal name |

|---|---|---|---|

| Primates | Cercopithecidae | Japanese macaque | Macaca fuscata |

| Rodentia | Muridae | Small Japanese field mouse | Apodemus argenteus |

| Unidentified murid species | |||

| Sciuridae | Japanese giant flying squirrel | Petaurista leucogenys | |

| Japanese dwarf flying squirrel | Pteromys momonga | ||

| Gliridae | Japanese dormouse | Glirulus japonicus | |

| Chiroptera | Unidentified bat species | Chiroptera | |

| Carnivora | Canidea | Common raccoon dog | Nyctereutes procyonoides |

| Mustelidae | Japanese badger | Meles anakuma | |

| Japanese marten | Martes melampus | ||

| Mustelidae | |||

| Viverridae | Masked palm civet | Paguma larvata | |

| Lagomorpha | Leporidae | Japanese hare | Lepus brachyurus |

| Artiodactyla | Suidae | Wild boar | Sus scrofa |

| Cervidae | Sika deer | Cervus nippon | |

| 6 | 10 | 11 |

Families and species were only counted if the family or species could be distinguished.

Birds identified

| Order | Family | Common name | Binominal name |

|---|---|---|---|

| Columbiformes | Columbidae | Oriental turtle dove | Streptopelia orientalis |

| White-bellied green pigeon | Treron sieboldii | ||

| Suliformes | Phalacrocoracidae | Great cormorant | Phalacrocorax carbo |

| Cuculiformes | Cuculidae | Northern hawk-cuckoo | Hierococcyx hyperythrus |

| Lesser cuckoo | Cuculus poliocephalus | ||

| Accipitriformes | Accipitridae | Black kite | Milvus migrans |

| Eurasian goshawk | Accipiter gentilis | ||

| Grey-faced buzzard | Butastur indicus | ||

| Strigiformes | Strigidae | Ural owl | Strix uralensis |

| Japanese scops owl | Otus semitorques | ||

| Northern boobook | Ninox japonica | ||

| Coraciiformes | Alcedinidae | Ruddy kingfisher | Halcyon coromanda |

| Common kingfisher | Alcedo atthis | ||

| Crested kingfisher | Megaceryle lugubris | ||

| Coraciidae | Oriental dollarbird | Eurystomus orientalis | |

| Galliformes | Phasianidae | Copper pheasant | Syrmaticus soemmerringii |

| Piciformes | Picidae | Japanese pygmy woodpecker | Dendrocopos kizuki |

| Japanese green woodpecker | Picus awokera | ||

| Passeriformes | Pittidae | Fairy pitta | Pitta nympha |

| Campephagidae | Ryukyu minivet | Pericrocotus divaricatus tegimae | |

| Monarchidae | Black paradise flycatcher | Terpsiphone atrocaudata | |

| Corvidae | Eurasian jay | Garrulus glandarius | |

| Large-billed crow | Corvus macrorhynchos | ||

| Paridae | Varied tit | Sittiparus varius | |

| Japanese tit | Parus minor | ||

| Pycnonotidae | Brown-eared bulbul | Hypsipetes amaurotis | |

| Cettiidae | Japanese bush warbler | Horornis diphone | |

| Aegithalidae | Long-tailed tit | Aegithalos caudatus | |

| Phylloscopidae | Eastern crowned warbler | Phylloscopus coronatus | |

| Zosteropidae | Warbling white-eye | Zosterops japonicus | |

| Certhiidae | Eurasian treecreeper | Certhia familiaris | |

| Troglodytidae | Eurasian wren | Troglodytes troglodytes | |

| Cinclidae | Brown dipper | Cinclus pallasii | |

| Turdidae | White’s thrush | Zoothera aurea | |

| Japanese thrush | Turdus cardis | ||

| Narcissus flycatcher | Ficedula narcissina | ||

| Blue-and-white flycatcher | Cyanoptila cyanomelana | ||

| Passeridae | Eurasian tree sparrow | Passer montanus | |

| Motacillidae | Grey wagtail | Motacilla cinerea | |

| Japanese wagtail | Motacilla grandis | ||

| Fringillidae | Grey-capped greenfinch | Chloris sinica | |

| Japanese grosbeak | Eophona personata | ||

| Emberizidae | Meadow bunting | Emberiza cioides | |

| 9 | 27 | 43 |

ReEDEN Project

The reeds of Lake Biwa play an essential role. They provide an aquatic habitat, support biodiversity, and absorb CO2. In the past, the reeds served as material for roofing and sudare screens, but with the decline of such traditional industries, the reedbeds are no longer maintained so well. The lake once had 260 hectares of reedbeds, but only half remains. In 1992, Shiga Prefecture passed an ordinance to address the problem by conserving, cultivating, and using the reeds. Believing that such action would preserve Lake Biwa’s beautiful environment and fight climate change, KOKUYO Product Shiga (which operates near the lake’s shore) launched ReEden Project in 2007 to raise awareness about the reeds and promote their use.

Conserving Lake Biwa’s reedbeds -Network for Protecting Lake Biwa Through Reed Management-

We have formed a network of partnerships for protecting Lake Biwa through reed management. The network had to suspend activities during the pandemic (KOKUYO Project Shiga continued managing the reeds on its own), but it resumed activities in February 2023. Membership of the network has grown with many companies resolving to continue sustainable-business initiatives and environmental initiatives and with many individuals recognizing that environmental initiatives are essential to secure a sustainable future. The network had formed in the first place on the understanding that local stakeholders should act together to address a local environmental issue that concerns them all. Now encompassing 132 companies that share the vision, the network engages in reed cutting three times every winter, from December to March. The network cut reeds in Lake Nishinoko on two occasions in February 2023, in Iba-Naiko in December 2023, in Lake Nishinoko on two occasions in February 2024, and it will cut reeds in Iba-Naiko in December 2024. Alongside winter reed cutting, the network helps organize and advertise summer events, including a fishing competition to clear away invasive fish species and an experience of canoeing around the reedbeds.

Reed cutting supports the environment because when the reeds grow, they absorb carbon dioxide and filter impurities from the water to a greater extent. During the pandemic, the reedbed area under management shrunk. Compared to reedbeds that are never trimmed, reedbeds that are periodically trimmed have ticker, longer, and more healthy reeds.

To expand the project outward, we have brought on board more stakeholders outside our network of volunteers. Since the project began in 2017, 35 activities have been held, with a cumulative total of 5,500 people participating. We will hold more activities in the future.

December 16, 2023: Winter reed cutting in Iba-Naiko with partners from the Iba area

February 10, 2024: Winter reed cutting in Nishinoko with partners from the Shimotoira area

How reed conservation can contribute to a low-carbon world: Showing the impact

In biomass surveys, predetermined samples of the reeds are cut from the reedbeds and their length is measured to derive an average length. The average length is then multiplied by the reed-cutting area to determine the amount of carbon dioxide the reedbeds are sequestering. This formula for calculating the CO2 absorption in reeds has been published on Shiga Prefecture’s website.

The findings are shared with the organizations and individuals participating in the network to guide their future environmental activities.

In 2023 (counting three rounds of reed cutting), 13.3 tons of carbon dioxide was sequestered over a project area of 12,600 square meters.

There is now a body of evidence to show how the project is contributing toward a low-carbon world. The data has demonstrated that the project is mitigating climate change in addition to improving the lake’s water quality and biodiversity. This knowledge has boosted participants’ motivation and brought more people on board.

The project team plans to expand the use of the tool with a view to benefiting the whole of the prefecture. The team’s vision is to follow up the carbon sequestration work in forests across Japan by developing an unprecedented carbon sequestration system for lakeside environments.

Measuring reed length as part of a biomass survey (in Iba-Naiko and Nishinoko)

External awards and recognition

Yuimori honored at 6th Eco Pro Awards

■ Description of award program

- Program organizer

Sustainable Management Promotion Organization

- Name of award

Commendation (Yushu sho)

- Awardee

Yuimori (brand of wooden furniture)

■ Comments from the judges

- The office furniture designs have cleared three hurdles to using Japanese conifers in wooden furniture: cost, resilience, and aesthetics. The sale of the furniture has environmental as well as economic benefits in that it contributes to better management of man-made forests in Japan, which are often desolate. With these benefits plus an aesthetically appealing design, Yuimori has a positive outlook.

- We commend the fact that, as well as clearing the hurdles to use Japanese conifers in wooden furniture through a three-way collaboration, the brand allows for easy recycling after the furniture reaches the end of its life.

- Yuimori is a brand of Japanese-made furniture inspired by the manufacturer’s forestry program.

- It is great to know that a big-name producer of office goods is interested in forest management. The manufacturer seems committed to engaging with the value chain and managing the whole life cycle of the product (rather than letting the sale be the end of the cycle, it creates value for second and third users too).

Yuimori honored at 2023 Japan Wood Design Award

■ Description of award program

- Category

Lifestyle design

- Sub-category

Products

The Wood Design Awards honors wood-related products and projects that benefit consumers in three ways: by improving life, by improving health, and by improving society. The purpose of the awards program is to promote an abundant life with wood, enriching people’s lives, stimulating demand for Japanese timber, and encouraging responsible forestry.

Endorsing the awards program, KOKUYO actively uses Japanese timber.

voice

Yuimori—a brand of sustainable wooden furniture

Some 40% of Japanese woodland consists of man-made soft conifer forests, which provide a source of softwood. With the rise in timber imports and the decline of the forestry industry, many of these conifer forests have been left to grow desolate. Key to restoring and preserving the natural functions of forests is to use as unwastefully as possible the timber that was harvested in these forests during thinning operations. By using such timber in manufacturing, we can contribute to a society that lives in harmony with nature. This belief inspired the brand Yuimori. One hurdle we faced was that the softness of conifer makes it hard to use as furniture material. Another issue was that, as an office furniture maker, KOKUYO mainly uses steel in its furniture products. To overcome these challenges, we engaged with partners who had expertise in designs and manufacturing technology that made adept use of wood (wood being the focus of the project) and combined their expertise with our own track record in manufacturing office furniture. The collaboration resulted in designs that bring out the natural feel of the wood, blend in with the interior space, and offer the resilience demanded by office furniture. We will keep protecting the forests of Japan to contribute toward a future in which Japanese timber features much more prominently in the furniture people use.

Workplace Business Division

Workstyle Marketing Division

Marketing Strategy Unit

Ms. Kawamura